•Feature

1.Cable drawing-out section is constructed to keep cables doubly by use of rubber packing and cable clamps.

2.Thermosetting epoxy resins have been employed for insulators.

3.Seven kinds of shell size and various shell type are available for a variety of applications.

•Order Cording

NWPC = Series designation

25 = Shell size

2 = Number of contacts

P = Shell shape

M = Contacts shape

_ = Symbol representing the outer diameter of the cable used

•Cable termination : Soldering

•Operating temperature range : -40°C to + 85°C

•Water resistance : Water pressure 0.5kPa 24hrs.

•Material and Finish :

1.Shell

- Material : Brass or Zinc alloy die casting

- Finish : Chrome plating

2.Insulator

- Material : Epoxy resin

3.Contact

- Material : Copper alloy

- Finish : Nickel, Silver or Gold plating

4.Plating

- Material : Synthetic rubber

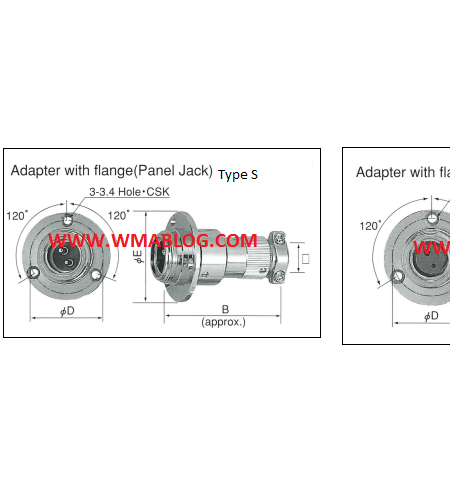

•Adapter with flange(Panel jack) Type S

1.NWPC-16*(F)_

- Number of contacts : 1,2,3,4

- B : 59

- D : 32

- E : 40

2.NWPC-25*(F)_

- Number of contacts : 2,3,4,5,6,7,8

- B : 72

- D : 39

- E : 47

3.NWPC-30*(F)_

- Number of contacts : 2,3,4,5,6,7,7H,8,13

- B : 80

- D : 44

- E : 52

•Adapter with flange(Panel jack) Type G

1.NWPC-16*AdF(F)_

- Number of contacts : 2,3

- B : 59

- D : 32

- E : 40

2.NWPC-25*AdF(F)_

- Number of contacts : 2,3,4,5,6,7

- B : 72

- D : 39

- E : 47

3.NWPC-30*AdF(F)_

- Number of contacts : 2,3,4,5,6,8

- B : 80

- D : 44

- E : 52

Orde Cording :

NRW : Series designation

20 : Shell Size

7 : Number of Contact

PM : Type of shapes if connector

_ : Symbol repsenting the outher diameter of the cable